Home Insulation: The Ultimate Guide

If you’re reading this article you’re likely researching home insulation. This can be a daunting task as there are a number of insulation options out there in the market. Further complicating the process is where and how to install home insulation. What follows below is our simple guide working through how, where, and even why to install insulation in your home.

Home Insulation Basics

Insulation prevents the transfer of heat, both in and out of your house. It helps maintain temperature, one of the four major control layers of any house – along with water, air, and vapor. Importantly home insulation does not air seal. It is simply there to prevent the transfer of heat. Air sealing is crucial for the performance of any home, as we have written about at length here , so make sure your home is air tight before beginning insulation work.

The most common way to measure insulation’s ability to prevent the transfer of heat is via R-value. The higher the R-value the better. We note that R-value is not the only way to assess the quality and the performance of insulation. In fact R-value calculations can often be inaccurate and won’t necessarily predict the true performance of insulation in a dynamic environment. Moisture management is also crucial to understand how insulation will perform when moisture inevitably gets inside your walls. If your insulation is unable to manage moisture, you can end up with soggy, wet insulation that no longer has the R-value it claims to.

Building Codes and Insulation

Understanding building code requirements is crucial when figuring out how much home insulation you need in your particular application. For the most part, building code is predicated on R-value. And generally speaking, in northern climates the building code requires a higher R-value. We always recommend paying attention to building code because failure to meet code can create a tremendous amount of problems. We’ve written an article here which helps simplify this process.

Different Types of Home Insulation

This is where your insulation journey can get even trickier. There are a ton of insulation options out there. Let’s break down the basics to simplify what options are available to you. But before we get to materials, let’s discuss the two main types of insulation.

Batt insulation is commonly used for a number of different applications. Batts resemble blankets and are designed to be stuffed into walls at a given thickness and a given width. The installation process tends to be pretty easy, though modifications are often required when dealing with obstructions in your wall like plumbing or electric.

Blown-in or loose-fill insulation is completely different from batts. The material tends to be loose fibers that are blown into a wall or attic with a specific machine. Blown-in insulation generally performs better as it ensures a tighter fit within the wall or ceiling cavity. And it will more easily wrap around obstructions like plumbing and electric.

Below are some of the standard types of home insulation currently in the market

Contact the Havelock Flock for help with your insulation project.

Havelock Wool = Sheep’s Wool

- Pros: high R-value, manages moisture, safe and easy to install, absorbs sound incredibly well, sustainable, healthy, compostable, fire resistant, mold and mildew resistant

- Cons: higher upfront cost than other, cheap insulation

Rigid foam

- Pros: relatively high R-value, can be cut for a precise fit

- Cons: energy intensive production, does not accommodate wall obstructions easily, decreasing R-value overtime, does not manage moisture

Fiberglass

- Pros: very low cost, batts can install quickly

- Cons: does not manage moisture, often contains toxic chemicals, energy intensive production, slumps and settles easily, releases glass particulate into the air

Mineral Wool

- Pros: comes in both batts and blown in, contains recycled materials, relatively high R-value

- Cons: energy intensive production, can contain toxic chemicals, does not manage moisture

Spray Foam

- Pros: fast installation done by professionals, good coverage when blown in

- Cons: expensive toxic off-gassing, can crack over time, does not manage moisture, not sustainable

Cellulose

- Pros: uses recycled materials, blown in ensures good coverage, somewhat sustainable

- Cons: can settle significantly, does not manage moisture well

Hemp

- Pros: more sustainable, healthier than traditional products, safer to install

- Cons: does not manage moisture, no blown-in option,

Where to Install Home Insulation

There are a lot of different places in your home where insulation can be installed. Some applications are easier than others and your choice of insulation may also be influenced by where you are installing it. The most common places for home insulation are the exterior walls, attics, interior walls, band joists, and crawl spaces. As we mentioned earlier, air sealing is a crucial component before installing insulation. So regardless of where you’re looking to insulate, make sure that air sealing has been done as well.

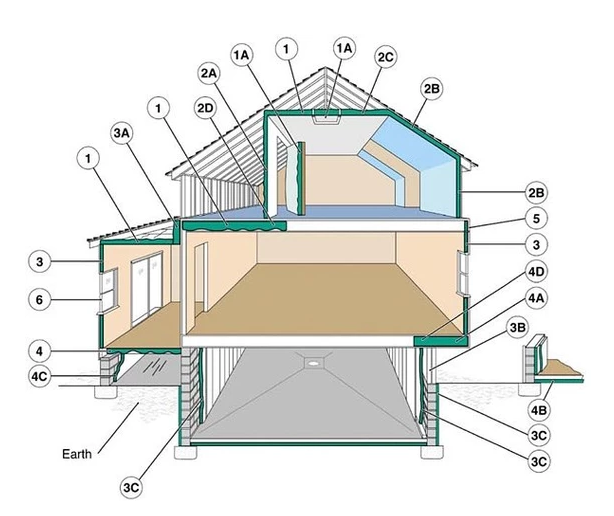

For optimal energy efficiency and performance, your home should be properly insulated from the roof to the foundation. This schematic shows those areas of a home that should be insulated.

1. Unfinished attic – In unfinished attic spaces, insulate between and over the floor joists to seal off living spaces below.

(1A) Insulate and seal the attic access door.

2. Finished Attic – In finished attic rooms with or without dormer, insulate (2A) between the studs of “knee” walls, (2B) between the studs and rafters of exterior walls and roof, (2C) and ceilings with cold spaces above.

(2D) Extend insulation into joist space to reduce air flows. Use baffles to avoid blocking soffit vents.

3. Exterior Walls – All exterior walls, including (3A) walls between living spaces and unheated garages, shed roofs, or storage areas; (3B) foundation walls above ground level; (3C) foundation walls in heated basements, full wall either interior or exterior.

4. Floors and cold spaces including crawl spaces – Floors above cold spaces, such as vented crawl spaces and unheated garages. Also insulate (4A) any portion of the floor in a room that is cantilevered beyond the exterior wall below; (4B) slab floors built directly on the ground; (4C) as an alternative to floor insulation, foundation walls of unvented crawl spaces. (4D) Extend insulation into joist space to reduce air flows.

5. Band joists.

6. Window jam – Single pane replacement or storm windows and insulate around all windows and doors with Havelock Wool Loose fill insulation or at least caulk and seal around all windows and doors.

In addition to insulation, consider moisture and air leakage control in each area of your house.

Can I Install Home Insulation Myself?

The answer is yes. Installing home insulation yourself can be an easy process. A lot will depend on where you’re installing insulation and what kind of insulation you’re installing. As mentioned above, many forms of blown-in insulation require specific machines to do the installation, not to mention PPE to limit exposure to toxic chemicals. However, there are types of insulation that you can install yourself.

Look for insulation that is safe, healthy, devoid of toxic chemicals and doesn’t require sophisticated machinery. The insulation industry came up with batts as a product for Non- professionals to install so those Products are commonly used by the DIY community. Increasingly, there are opportunities to use blown-in machinery for everyday DIY’ers. And Havelock wool we provide a simple machine that really anyone can use to blow insulation into any type of application. We provide all the resources to get you up and running fast to do your own installation project

Tools and Materials You Might Need for Your Home Insulation Project

- Knife for cutting insulation

- Tape measure

- Pencil

- hammer

- protective eyewear and gloves

- Stapler

- insulation hangers for batts

- Netting for blown-in insulation

Figuring out How Much Insulation You Need

So you’ve identified an area in your house, whether it’s a bedroom, an attic or even the basement, that requires insulation. The next step is to determine how much insulation is required for the project. You’ll need to know the square footage of the area which is simply length multiplied by width. For example, an 8-foot high wall that runs 10 feet long is 80 square feet (8×10=80). You’ll also need to account for the depth of the area to be installed. Standard wall framing uses either 2×4 or 2×6 studs and batt insulation comes specifically sized for these dimensions. So if you’re using bats the process is relatively simple. Once you’ve figured out the square footage, just determine the framing size and then choose those batts that fit. (One important thing to note is that 2×4’s are actually 3 1/2 inches deep and 2×6’s are 5 1/2 inches deep).

Determining your blown-in insulation requirements may require you to figure out the cubic footage of the area to be installed. This is done by simply multiplying your square footage by your depth (as expressed in feet). For example, 80 square feet at 6 inches depth is 40 Cubic feet. 80 x 0.5 = 40.

Or you can skip all this math and simply use our simple home insulation calculator which calculates your requirements for either batt or blown-in insulation.

Finding an Insulation Installer That’s Right for You

If you’ve decided that you want a professional to take care of your insulation project, then you’ll need to find the right fit for you. Unfortunately, the insulation industry is filled with professionals who focus on speed, not quality, of installation. Further many professionals only work with traditional insulation products which may be toxic and low quality. However, as consumer awareness has increased around healthy insulation materials there are more installers out there that are willing to work with the proper materials and to do a project correctly. Our suggestion is to take your time when choosing an installer and make sure that their interests are properly aligned with yours. At Havelock Wool, we work with some dedicated installers because of their focus on installing healthy home insulation, like wool, properly. Check out this video that we put together which showcases one such installer.

The Cost of Home Insulation

Before we get into the details, let’s look at insulation at a higher level. In terms of the overall cost of building a new home, insulation is roughly 2% on average of the total construction cost. To put it in context this is on par with lighting fixtures and plumbing and less than half the total cost of cabinets and countertops. This relatively low cost of insulation is skewed by the preponderance of very low cost, ie cheap, insulation, in particular fiberglass. This has always struck us as odd given how important insulation is for the performance, health and efficiency of your home.

Below are some headline costs based on different types of insulation. But be aware that insulation costs can vary based on the region that you’re in, so it’s always important to check what’s available in your area to understand accurate costs.

- Cellulose averages $1.20 per s/f

- Fiberglass is generally $0.64 – $1.50 per s/f

- Rockwool averages $1.70 per s/f – according to homewyse

- Cotton is generally 0.76 – $1.41 per s/f – according to Homeguide

- Wool is specifically $1.70 per s/f for batts and $1.75 – $2.81 for blow-in*

- Open-cell spray foam is generally 35 to 55 cents per board foot**

- Closed-cell spray foam is generally $1.00 – $2.00 per board foot**

** A board foot is 1 square foot with material applied @ 1” thickness. The foam figures need to be multiplied by the number of inches installed eg 3” of closed cell foam is $3.00 – $6.00 per s/f in the example above.

Contact the Havelock Flock for help with your insulation project.

Insulation Terms You Should Know

During your installation journey, you will undoubtedly run into some new language But fear not, we are here to help. Below we’ve compiled some of the jargon and terminology you may run into. Just knowing the basics will help you move faster along your installation journey.

R-value is the resistance value of the insulation i.e. the limiting factor for thermal conductivity. The higher the number the more insulated the space.

Thermal bridging is when outside temperatures are conducted inside and vice versa. Think of a structural metal beam that runs from the outside, in. When that beam transports cold air to the inside of the structure – that is thermal bridging.

Air tightness is an increasingly measured element in building. An air-tight structure is considered more efficient. Often it is.

A convective loop is the cycle of air inside a room resulting in heat loss. Warm air rises, cold air flows downward.

Wind washing is when wind drive blows air through walls and insulation. Not only can this make your home cold (or hot) but it can also cause condensation.

Vapor drive diffuses moisture vapor into and through walls which causes condensation. It can move from outside to inside a house or inside to outside.

Types of Insulation:

Batts are precut insulation designed to fit into specific cavities.

Loose-fill is a blown application generally seen to reduce the potential for gaps in cavities.

Facing is a covering applied to one side of insulation. Popular with fiberglass… not necessary for wool.

A vapor barrier is any material (typically a poly film) used to resist the diffusion of moisture (or vapor drive… see above!)

Insulation Metrics:

R-Value (again) measures insulation’s resistance to heat flow. As R-value increases, the better the insulation resists the transfer of heat.

Flame spread and smoke development measure resistance to flame and how much smoke is developed. Most insulation conforms to Class A of the building code by adding various chemicals. Wool does it naturally.

Sound transmission coefficient (STC) is a rating scale used to measure the sound rating or deadening ability of a wall.

Noise reduction coefficient (NRC) is similar to an STC except that it measures a material’s sound attenuation characteristics….versus a wall system which can have multiple components.

WUFI is the measure of an insulations ability to manage moisture.

Building Terms:

Joists are lengths of timber (or steel ,etc) arranged in parallel to support floors or ceilings.

Studs are vertical framing pieces, usually wood and typically 2×4 or 2×6.

Furring strips are wood or other material used to level a surface to which insulation can be attached.

Rim joists attach perpendicularly to the joists providing support for the ends of the joists while capping off the end of the floor.

On Center (O/C) is the measurement from the center of one stud to the center of another stud.

Eaves are the part of the roof that overhangs a wall.

Soffit vents are vents in a soffit (underside of an eave) that allows fresh air into an attic.

Baffles are chutes that channel from soffit vents into attic space. This helps reduce moisture in your attic.

Attic vents are placed on a roof to allow air flow.

A ridge vent is installed at the peak of a roof to allow air flow in an attic.

Additional learning resources

Insulation doesn’t need to be a confusing topic despite the best efforts of some players in the industry. The reality is that insulation can be very simple and in fact, most people can install installation properly themselves. Throughout our journey of educating people about healthy insulation, we’ve established relationships with a number of other like-minded people and companies. Below is a list of great resources for anyone who’s trying to educate themselves about not just home insulation but healthy building in general.