We are Sustainable, Healthy,

High-Performance Insulation

Our Products

About Batts

Why choose Batt Insulation?

Batt insulation is akin to a large blanket designed specifically to fill a wall, floor or ceiling cavity. With a perfect friction fit any installer can quickly place our PRO batts into the cavity at the same pace as conventional batts, or faster. Though no protective clothing is required. It is importatnt to note that perfect cavities sizes are rare so great attention needs to be taken to split, cut, and modify batts to fit around obstructions or else the performance is severely compromised.

How to Install Batt Insulation

Batts are typically cut at 46.5” meaning two batts fit in a standard cavity. Unfaced batts are applied with friction in both wood and metal cavities. This video covers all aspects of batt installation: tools and materials needed, job site preparation and technique.

About Blown-In

Why choose Blown-In Insulation?

Our blown-in insulation consists of “knops” or balls of wool that are incredibly effective at trapping air, thus offering R4.3 per inch. The wool is blown into a wall cavity ensuring maximum coverage, i.e. no gaps. Naturally, wool expands slightly over time which means no slumping especially in the presence of moisture or water. Other blown-in insulation absorbs water like a sponge, gets heavy under its own weight, settles to the bottom of the cavity and attracts mold.

How to Install Blown-In Insulation

Small jobs can be done via hand-stuffing but medium to large jobs go well with our electric blower or an insulation removal vac. Some simple prep and a few basic tools will have your living space insulated in no time. Anyone can install our blown-in insulation!

Why Wool

Why Should You Insulate Your Home with Havelock Wool?

Moisture Management

Actively managing moisture is paramount in today’s built environment. Construction techniques are increasingly air-tight. This creates challenges for vapor drive. Including an insulation that absorbs and later releases moisture improves indoor air quality, regulates temperature and keeps your home free of mold and mildew.

R Value

Insulation is commonly measured by R value. In short, it is a measure of resistance to thermal conductivity; the higher the number the better the resistance. Havelock is an impressive R3.6 per inch for batts and an outperformer at R4.3 per inch for blown-in.

Air Quality

Not only is Havelock Wool devoid of harmful chemicals, it helps absorb them. A coarse wool fiber has the rare ability to absorb and regulate concentrations of indoor pollutants within your building – notably formaldehyde, NOx and SO2. The EPA tells us indoor air quality can be up to 5x worse than outdoor air. Wool insulation in the structure can help improve the air you breathe.

Sound Absorption

Havelock Wool excels at absorbing sound and reducing unwanted noise. Noise reduction coefficients (NRC) for batts and blown-in are 90 and 95% respectively. A quieter living space is conducive to a more relaxing and enjoyable place to call home.

Sustainability

Havelock Wool is renewable and sustainable. The fibers we use have evolved as an insulator over 1000s of years. Our production process is incredibly low impact as we employ time-tested textile manufacturing techniques – as opposed to high heat. At the end of an extended useful life that will last the life of the structure, wool insulation is biodegradable and compostable.

How Wool Compares

How does wool stack up against traditional insulators?

Detailed comparisons: air filtration, moisture management, insulation performance, sound absorption, sustainability, and installation.

What Homeowners Say

Easy to Buy & Install

Install Havelock Wool in your home today.

Installation

Check out our complete installation video!

Estimate & Purchase

Ready to buy?

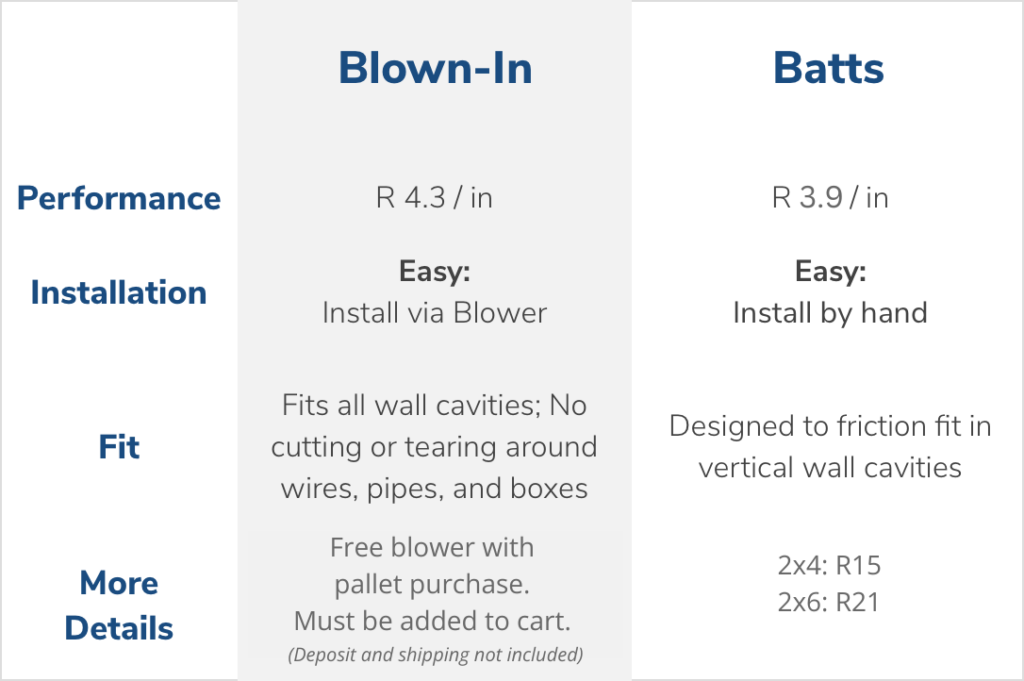

Havelock Wool offers you the choice of either Batts or Blown-In (Loose Fill) insulation.

Click here for detailed instructions on estimating how much wool you need, then visit our store:

Detailed Drawings of Common Applications:

Download HERE

Frequently Asked Questions

PRO batts are R15 and R21 for a 2×4 and 2×6 respectively. Loose-fill is R4.3 per inch so just multiply by the cavity depth.

The amount of insulation is measured by the amount of wall, floor or ceiling / roof space you need to insulate. It is not the s/f of your house. Once you calculate the actual square footage of the space you need to insulate and the associated cavity depths you will understand how much insulation is required. We built a calculator here to help.

We only recommend using a vapor barrier on the ground in a crawl space. Vapor variable membranes can help create air tightness and in turn efficiency in the performance of a home but for sure a pure vapor barrier has no place in the walls or roofline.

No. We’ve not had an issue in over 10 years.

We apply a minor amount of boric acid (less than 1% by weight), which is all-natural and non-toxic, as an insect repellent. In addition, it is often the lanolin that attracts pests. Our wool comes from New Zealand where the most advanced scouring (cleaning) techniques in the world are employed to ensure a consistent, clean fiber that is provided for our process.

The batts we make for vans are R7 @2” thick.

We’ve tried to make this as easy as possible. First and foremost you can buy everything we make on our website here. In addition, we made our PRO batts with professional installers and builders in mind. The adoption rate is going quite well so we hope and expect you can also source our products from your local installer now or in the near term.

We’ve tried to make this as easy as possible. First and foremost you can buy everything we make on our website here. In addition, we made our PRO batts with professional installers and builders in mind. The adoption rate is going quite well so we hope and expect you can also source our products from your local installer now or in the near term.

Our factory is in Reno, NV and we ship all over the US and Canada.

We can ship to your jobsite or an installer near you. See full shipping details here.

Yes. Havelock products conform to Class A of the building code. Test results are available and no exception is needed to use Havelock Wool.

And finally, if you have other questions please click here to find over 175 questions and answers.