Our Message on Sustainability

The sustainability conversation has never attracted so much attention. Europe is introducing an end of life tax for products that are not recyclable or biodegradable, and we are not far from large organizations having to sign off on supply chain and operational footprints.

Insulation plays a unique role in this discussion. It helps reduce an operational footprint of a building, but it has one of its own too. In fact, incumbent insulation manufacturers are often some of the largest energy users in their area. So how do they address sustainability? Simple, they tell you they save more energy than they use. This argument might work when comparing oneself to oneself. But what if that structure used an alternative insulation that was more effective, longer lasting, came from nature, and was biodegradable?

Where does your insulation come from?

The marketing departments of these large organizations do a great job deflecting reality and storytelling in a way that if you don’t stop and think you might believe.

We have played along in the industry’s development of standards and we find most of them start with the right intention but never avoid the inevitable hijacking of the standard to suit the worst offenders.

We can’t control what happens in that arena but we can encourage any of our would-be users to employ the slightest amount of common sense.

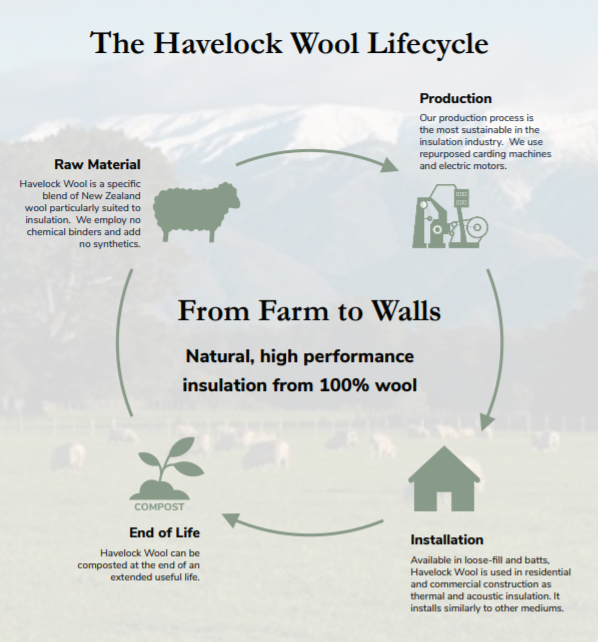

To clarify, the steps are as follows:

- Sheep eat grass fed by rainfall.

- Sheep wool sequesters some 525k tons of atmosphere-derived carbon per year

- Sheep fart (with incredibly less emission than cows)

- Wool is clipped and scoured (cleaned). The latter is water intensive and is done in NZ where 85% of the freshwater flows into the ocean. The water used to clean the wool is captured and used as effluent.

- Wool is packaged and shipped at maximum density – nearly 20k Kgs in a 20 ft container

- Wool is received and processed on carding machines with electric motors that consume almost no power

- Finished products are packaged and shipped

- Shipping insulation is the worst part of what we do. We meet or exceed industry standards but as a small business we are forced to ship from one facility. We plan to have more before too long

- And finally after outperforming the competition wool can be composted at the end of the structure’s life.

So there you have it. The lifecycle of wool is unlike any other product on the market. We won’t take the time to address the others but we will ask you to just stop and think about what it takes to make and eventually dispose of fiberglass or mineral wool (not real wool) or even foam insulation. Landfill is the best result and floating in the ocean forever is likely the worst.

As ever, use common sense and make informed decisions if you want to achieve a great result in building with sustainable insulation.