Havelock Wool insulation is not cheap. We would certainly argue it is full value and inexpensive when you account for everything it does (and does not) deliver. But in no way, could we ever say it’s cheap. It’s a premium product. Full stop.

Why does Havelock cost more?

A main reason is our raw material which is sheep’s wool from New Zealand. Havelock Wool comes from a specific kind of sheep, Romney. Their wool is ideally suited for insulation as it has just the right amount of crimp and loft. But it does cost money to raise and shear these lovely animals. Further, our wool is scoured (washed) and treated with a slight amount of boric once it has been sheared. This results in a very clean, consistent, fire-resistant material that is now suitable for insulation. The raw materials for traditional insulation are by comparison much cheaper… sand, soda ash, formaldehyde, isocyanate, basalt, slag, and polyurethane to name just a few. Many of these are simply products of wasteful industrialization and unlike wool, are not designed specifically to be insulation. The main reason why these materials are used for insulation is that they are cheap and abundant. We use wool for insulation because of its performance and sustainability.

You get what you pay for

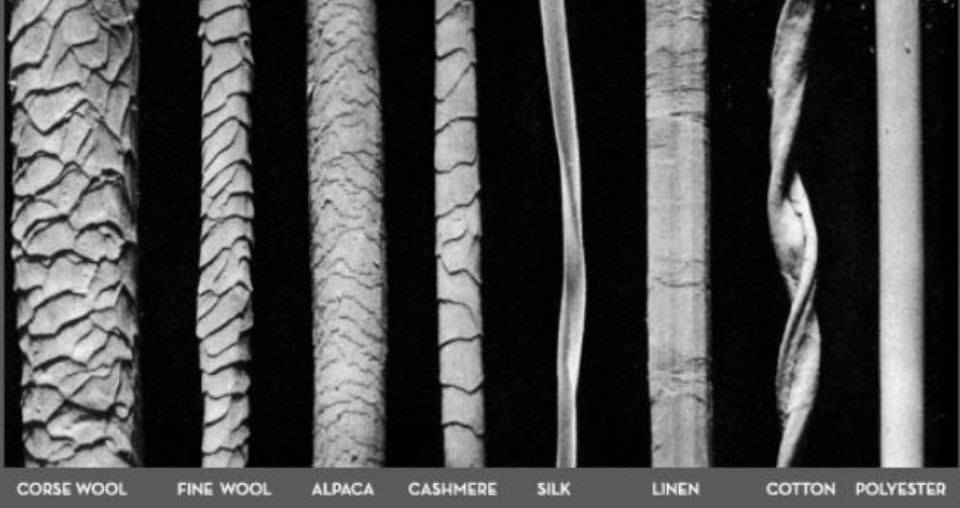

We love the below picture as it really shows how dynamic a coarse wool fiber is. There is just a ton going on with wool compared to any other fiber, especially those used in conventional insulation. Wool has evolved as an insulator for 10,000 years – not in an R&D department over the last 100. Accordingly, wool is dynamic and truly multi-dimensional. The outside of the wool fiber is comprised of overlapping scales called cuticle cells. The cuticle cells provide a strong exterior, protecting wool from damage. The cells have a waxy coating, lanolin, which makes wool water-repellent but they also have tiny pores allowing vapor to pass in and out of the fiber. This is how we get moisture management or hygroscopic properties from wool.

In an ingenious display of evolution the inside of a wool fiber, the cortical cell, is actually arranged in two distinct halves. These two halves respond differently to the environment which makes the wool fiber bend or crimp. This crimp is crucial because it creates bulk and traps a large volume of air between the fibers. And this makes for a good insulator. (Trapping of air in a wall cavity is the best way to insulate a structure as air is a terrible conductor. Wool not only traps air in the cavity but also in the fiber. There is nothing else like it. The crimp along with the aforementioned cuticle cells also prevents dirt from entering the fiber. Clean and warm!

Looking even further into the fiber we see inside the cortical cell a spring-like structure, which gives wool its flexibility and elasticity. For example… a wool fiber can be bent on itself over 20,000 times! Further, this spring-like structure is surrounded by a matrix containing high sulfur proteins that readily absorb water molecules… which again helps with moisture management.

The interior composition of wool also explains its resistance to fire and its ability to self-extinguish. Wool has high nitrogen and water content so it needs higher levels of oxygen to burn than the surrounding environment provides. In addition, wool’s cross-linked cell membrane structure will swell when heated to the point of combustion, forming an insulating layer that prevents the flame spread. This also means that wool produces less smoke and gas than synthetic fibers and synthetic insulation for that matter.

But should insulation be cheap?

The traditional insulation industry is all about speed and cost. Using a cheap material requires high volume to compensate for low margins. Indeed, a key marketing message for Owens Corning is “Make the Most of Every Minute…. Insulate up to 161 more homes per year”. They don’t even try to hide the fact that by choosing their material a builder or installer can move on to another project hastily. Herein lies a key philosophical difference between the status quo and Havelock Wool. We believe that insulation is a crucial part of your home’s performance and health. It is not an area to cut corners because the long-term benefits of healthy, high-performance insulation far outweigh the temporary cost savings you get with cheap insulation. Currently, insulation is around 2% of the total cost of a typical new home build which is way less than typical vanity items like faucets, countertops, and lighting fixtures. Now don’t get us wrong, we love a good-looking interior that functions well but the imbalance in budgets between aesthetics and performance is too severe.

Making wool more competitive

All that said, we are working hard to make wool more accessible to everyone. Our raw material will never compete on price with the standard competition but there are aspects of insulation’s cost structure that we can control. Installation is one of them. We have made a big push into the DIY market specifically with our blown-in product. Historically blown-in insulation was the domain of professionals but we believe everyone can install this high-performance product. We now provide tools and resources so that you can install it yourself and save a ton of money by not paying an installer or contractor. New product development is also a focus for us, specifically with batts and we will have more news on that in the coming months. Stay tuned.

Two comments. It may have evolved, or was it designed? :). Also I’m about to start a home build in Toronto, Canada. Will need insulation in early 2023, and I’d like to figure out budget/logistics for havelock. Cheers.

I’d like to see your price list please. I’m about to do a major renovation and am interested in Havelock insulation for our home. Thanks!

I insulated our house and it is sooo easy and lovely to think of being surrounded by it. It cost a little more but non flammable doesn’t rot ,if it gets wet it dries and besides everything costs more now. Highly recommend!!

I have ordered a new Papago camper van that uses Havelock for insulation. They don’t use a vapor barrier, typically. As I plan to ski and camp 60 days in a row at subfreezing Temps, I understand that the natural breathing, moisture/condensation at those temperatures may not allow for removing accumulated moisture (breathing, cooking, hot showering. Would a vapor barrier install be advisable?

Vapor barriers are not your friend in a van. They are really only meant for crawlspaces in a house and should be applied to the dirt – not the walls or ceilings.