As our following in the residential insulation space grows, we receive more and more questions about general building practices. One topic that is particularly popular now is roof assemblies, specifically vented and unvented.

Common Approaches to Roof Venting

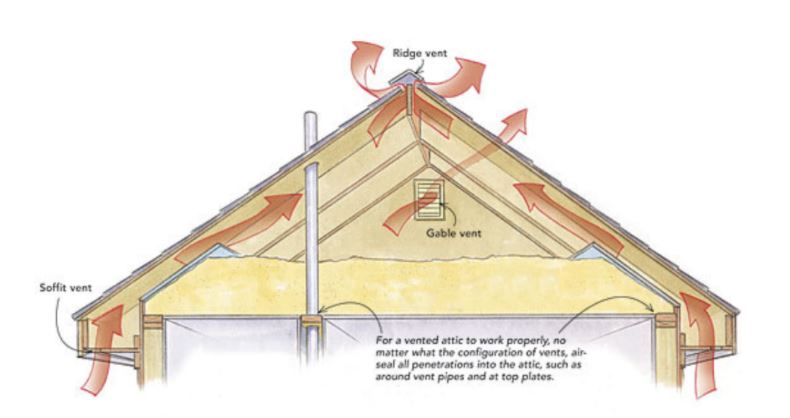

A Vented Attic is a tried and true building approach and one that is incredibly effective. The basic premise is to air seal your ceiling, insulate your attic floor and allow for air flow from the soffit to the peak. The result is an unconditioned attic but a well insulated living space. Problems occur when the ceiling is not actually air tight (recessed lights!), mechanical systems in the attic impede insulation (duct work!) and air doesn’t flow freely (wind washing!). However, if you can manage for these issues, a vented attic makes for a long lasting roof and helps a home perform incredibly well.

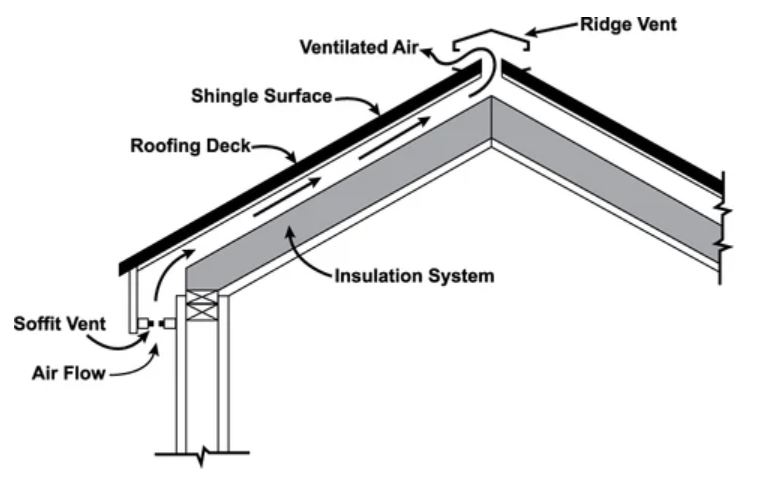

A Vented Roof allows for air flow into soffits while connected to a ridge or gable vent with baffles or channel vents. The main advantages here versus a vented attic is that a vented roof provides more living space (think cathedral ceiling) while managing attic moisture and controlling roof deck temps. The tricky part is when the roof line is complicated. Hips, valleys, dormers, or skylights make venting a roof pretty difficult as they often interrupt the rafter bays. And a vented roof needs the insulation to sit underneath an air flow gap.

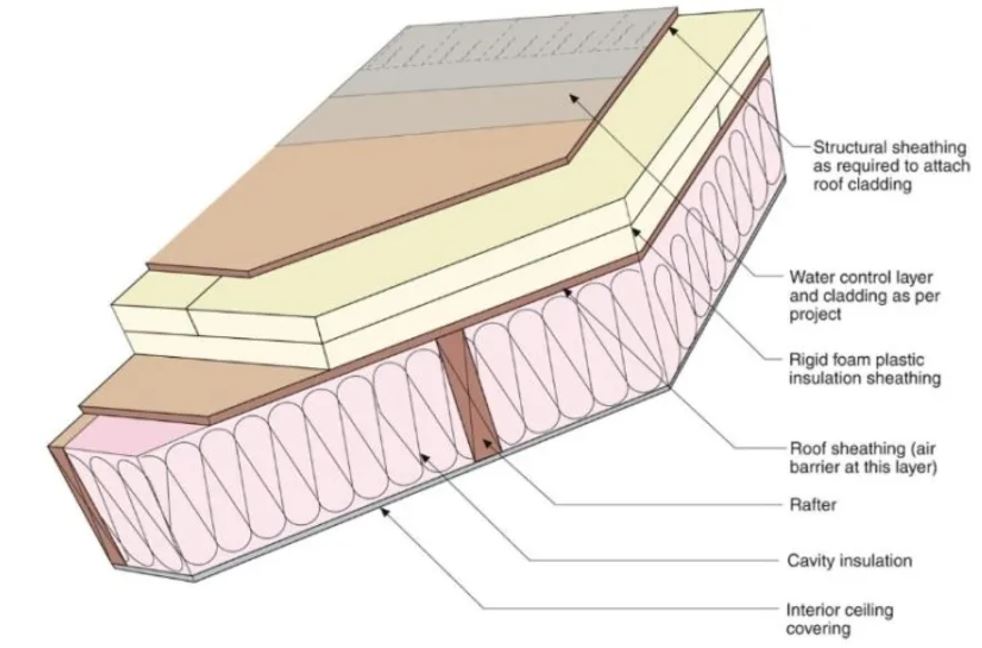

Unvented roof assemblies, like conditioned attics and unvented cathedral ceilings, are now pretty commonplace in North American building. Indeed, we get lots of questions from homeowners about this methodology. The core premise is to remove ventilation openings while moving the thermal, moisture and air control boundaries to the roof deck plane, or put another way, the assembly is sealed on all sides and filled with insulation. One key advantage to an unvented system is that your attic and living space are conditioned the same so air can move freely without wasting energy (unlike a poorly sealed attic space). The construction of an unvented roof assembly involves a few key components, notably cavity insulation, air barrier and water barrier.

What is better and why?

There are positives and negatives to each approach. We are not here to make a decision one way or the other, but highlighting considerations for each is important.

The argument for an unvented roof may start and stop with the need or desire for more conditioned space. An unvented roof allows for this.

Considerations for not venting should arguably begin with an understanding why a roof is vented in the first place. Exhaust vents are installed at the top of the roof. Their main objective is to provide an exit for the heat, toxins and moisture trapped in your attic. By not venting your roof you have not removed these challenges so, if you cut off their exit then where do they go? Another important aspect of venting is maximizing the longevity of your roof. Allowing the roof to experience air flow and (ambient) temperature change reduces stress and, in turn, wear and tear on the materials.

So before we consider the performance it is only fair to pause for a moment and consider the indoor air quality challenges now that you don’t have venting in the roof line. Are there measures that can be taken? Of course. Are they typically addressed? Good question; the fair response is not really or at least not accurately.

Conventional ‘wisdom’ surrounding an unvented roof is that enough foam insulation will push the dew point to the outside thus removing moisture challenges within the assembly. Physics might suggest this is true but it would also presume a flawless install and no settling over time. In an applied scenario these imperfections can create grave consequences. When vapor gets behind the foam there is no escape route; rot and mold is very likely to then become your new neighbor. This has happened time and again and we have written extensively about the challenges of foam. We will not relive that here as the topic is vented or not.

A growing practice that seems to solve these issues is exterior insulation. A continuous wrap of the exterior allows for many of the thermal barrier challenges to be addressed before piercing the envelope. We suggest reaching out to your local building scientist to learn more. Suffice to say, if any of us were currently building a home this is the path we would follow.

In sum, the argument for vented versus unvented roofs often comes down to an architect’s play book or a desire for more space within the house, or both. The simple fact is unvented roofs pose real challenges and getting more space can be achieved while maintaining a time-tested application that involves allowing for air flow. As ever, we only suggest being vigilant and making yourself aware of the advantages and disadvantages of whatever choice you make.

Look forward to the information you send. Always pushes me to know more. Thanks!

Sincerely thank you! We try really hard to help people make informed decisions about the building envelope. We’ll keep at it but encouragement is very well received!

We regularly work with both assemblies, but please note that rigid insulation does not need to be “plastic” – it can be wood fiber (such as Gutex), cork (Thermacork), or mineral wool(Roxul, etc). The first 2 options sequester carbon, and, while mineral wool requires carbon to make, it has excellent fire-resistance. And perhaps one day there will be a wool-based rigid board!

Hi Anni. Thanks for your note. Yep, totally agree, hence the comment re exterior insulation. We would note that Rockwool will burn a reported 84 tons of coal per day in West Virginia which is one of their 40+ factories. That aside, we are working on a wool option and just hope more specification of all the great products out there becomes more mainstream. Thanks for the support!