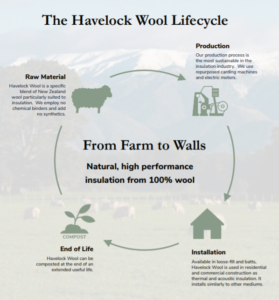

Our process is uniquely simple. We procure raw material (wool) in New Zealand, send it to ourselves in Nevada where we run a lite-touch manufacturing process, package roughly 6 different SKUs and send those products to distributors, trade members and directly to end-users. The below infographic shows the simplicity of our lifecycle.

Why Wool?

Coarse wool fibers are probably the most dynamic on the planet. They have evolved in nature’s R&D department over 1000s of years, as an insulator. Wool is great at attenuating sound, manages moisture, absorbing harmful chemicals (NOx, SO2 and formaldehyde); it insulates better and longer and is naturally self-extinguishing. It is also easy and fun to work with, particularly when compared to its toxic brethren.

Sourcing Wool

NZ has an abundant supply of wool – particularly the type we use for insulation. It is a coarse wool fiber. It is extremely dynamic, has five follicles, and some say it is the most capable fiber on the planet. We have a sourcing partner that helps us plan and price wool on a forward basis – typically 12 months. The scourers or cleaners of wool in NZ are arguably the best in the world. The industry is a measurable component of NZ’s GDP which means they are constantly striving to improve. The actual process is somewhat water intensive. Roughly 85% of NZ’s fresh water supply runs, unabated, into the ocean, which means scouring there makes a lot of sense.

Manufacturing in Reno

We run our own manufacturing process here in the US; aside from raw material sourcing everything we do and make happens right here. Our machines, our products and our people are in Reno, NV. We run old, repurposed carding machines and a whole host of self-fabricated transfer, cutting and packing stations. We pull very little power to run electric motors and an air compressor; labor demands are equally minimized as we are a small operation that does not require hundreds of workers. Where possible we have invested in automation so in fact each production line can be run with 3-5 people. This is relevant in our current environment for many reasons – not least workers are spaced 10 ft+ apart and we can run multiple lines without congregating more than 10 folks.

Shipping

Once products are created they are shipped in quantities ranging from one bag to a full truck load. We sell to #vanlifers, homeowners, distributors, insulation contractors, builders, designers and developers. We have and continue to evolve our business to address the growing interest in direct-to-consumer sales. We value every one of our partners and are driven by one goal: get some wool in as many building projects as we possibly can. Accordingly, we literally ship direct to job sites more than anywhere else.

Who Cares?

Well, we do for sure, but we also hope you do too. Some say our products are the ultimate in DIY insulation. It is wool, all wool. You don’t need gloves, a mask and protective clothing to install it. In fact, someone once said it is borderline fun to work with. So, if you are home and taking on overlooked projects, as we are, you may well have additional insulation needs in the attic or crawl spaces or both. If so, we can help with an otherwise daunting task by shipping directly to your door.

If you want to tick off one more item on the to-do list and improve the indoor air quality and general liveability of your home, give us a shout; we can ship to your door and provide all the instruction you need to make it happen.