We are Sustainable, Healthy,

High-Performance Insulation

Our Products

About Blown-In

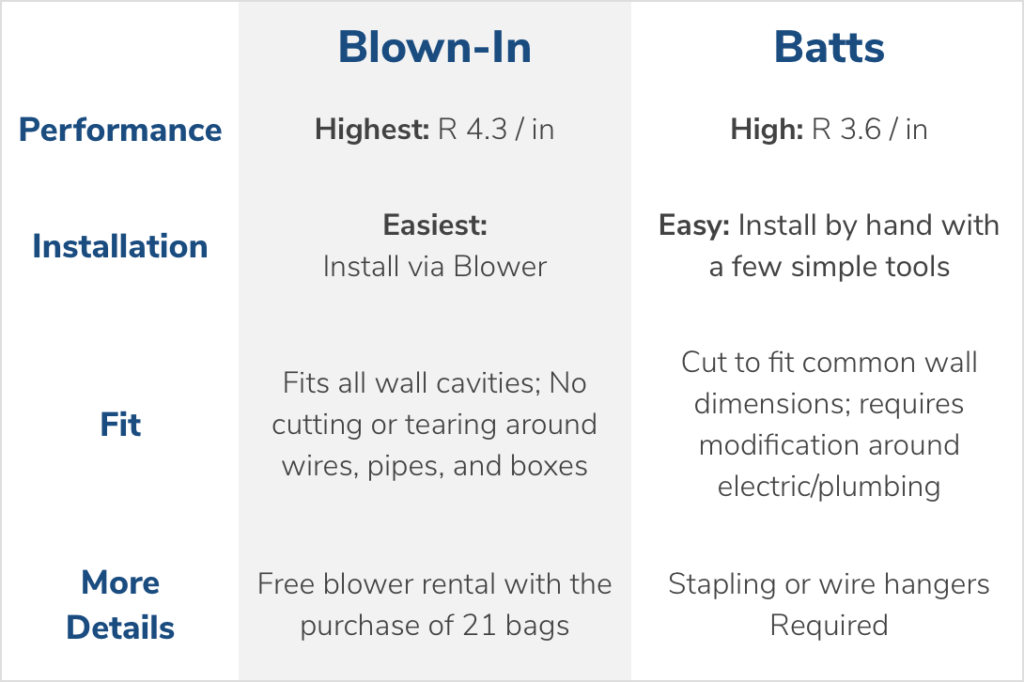

Blown-in insulation used to be just for professionals but now Havelock is bringing this high-performance insulation to everyone. Our blown-in insulation consists of “knops” or balls of wool that will work with any type of insulation project. The wool is blown into a wall cavity ensuring maximum coverage, i.e. no gaps. The wool expands slightly over time which means no slumping especially in the presence of moisture or water. Other blown-in insulation absorbs water like a sponge, gets heavy under their own weight and settles to the bottom of the cavity and attracts mold.

Small jobs can be done via hand-stuffing but medium to large jobs go incredibly fast with our electric blower. Some simple prep and a few basic tools will have your living space insulated in no time. Anyone can install our blown-in insulation!

About Batts

Batt insulation is akin to a large blanket designed specifically to fill a wall, floor or ceiling cavity. Batts were developed with the consumer in mind as they are ideal for perfectly sized modern framing with few electrical and plumbing obstructions. Quickly place them into the cavity and you are ready for drywall and finish work. They have been adopted by the construction industry as more installers looked for faster and less expensive methods to finish projects. Beware that perfect cavities rarely exist and great attention needs to be taken to split, cut, and modify batts to fit around obstructions or else the performance is severely compromised.

Batts are typically cut at 48” and may need to be stretched slightly upon removal from packaging. Unfaced batts are applied with friction. A staple may be added at the installer’s discretion. Wire or lightning rods may be used in a ceiling joist or with metal framing. This video covers all aspects of batt installation: tools and materials needed, job site preparation and technique.

Why Wool

Why Should You Insulate Your Home with Havelock Wool?

Moisture Management

Actively managing moisture is paramount in today’s built environment. Construction techniques are increasingly air-tight. This creates challenges for vapor drive. Including an insulation that absorbs and later releases moisture improves indoor air quality, regulates temperature and keeps your home free of mold and mildew.

R Value

Insulation is commonly measured by R value. In short, it is a measure of resistance to thermal conductivity; the higher the number the better the resistance. Havelock is an impressive R3.6 per inch for batts and an outperformer at R4.3 per inch for blown-in.

Air Quality

Not only is Havelock Wool devoid of harmful chemicals, it helps absorb them. A coarse wool fiber has the rare ability to absorb and regulate concentrations of indoor pollutants within your building – notably formaldehyde, NOx and SO2. The EPA tells us indoor air quality can be up to 5x worse than outdoor air. Wool insulation in the structure can help improve the air you breathe.

Sound Absorption

Havelock Wool excels at absorbing sound and reducing unwanted noise. Noise reduction coefficients (NRC) for batts and blown-in are 90 and 95% respectively. A quieter living space is conducive to a more relaxing and enjoyable place to call home.

Sustainability

Havelock Wool is renewable and sustainable. The fibers we use have evolved as an insulator over 1000s of years. Our production process is incredibly low impact as we employ time-tested textile manufacturing techniques – as opposed to high heat. At the end of an extended useful life that will last the life of the structure, wool insulation is biodegradable and compostable.

How Wool Compares

How does wool stack up against traditional insulators?

Detailed comparisons: air filtration, moisture management, insulation performance, sound absorption, sustainability, and installation.

What Homeowners Say

Easy to Buy & Install

Install Havelock Wool in your home today.

Installation

Check out our complete installation video!

Estimate & Purchase

Ready to buy?

Havelock Wool offers you the choice of either Batts or Blown-In (Loose Fill) insulation.

Click here for detailed instructions on estimating how much wool you need, then visit our store:

Detailed Drawings of Common Applications:

Download HERE

Frequently Asked Questions

Why Wool?

In the form of vapor, condensation or water- moisture will inevitably make its way into your walls. You need an insulation that actively manages that moisture, helping keep your house dry and free of mold and mildew. Unlike any other insulation, wool is naturally able to absorb moisture while still retaining it’s high insulative properties. When the ambient air dries (>65%) wool will release the moisture into the air. The result is a long lasting, non-slumping, high performance insulation that keeps your walls dry, temperatures more constant and energy bills low.

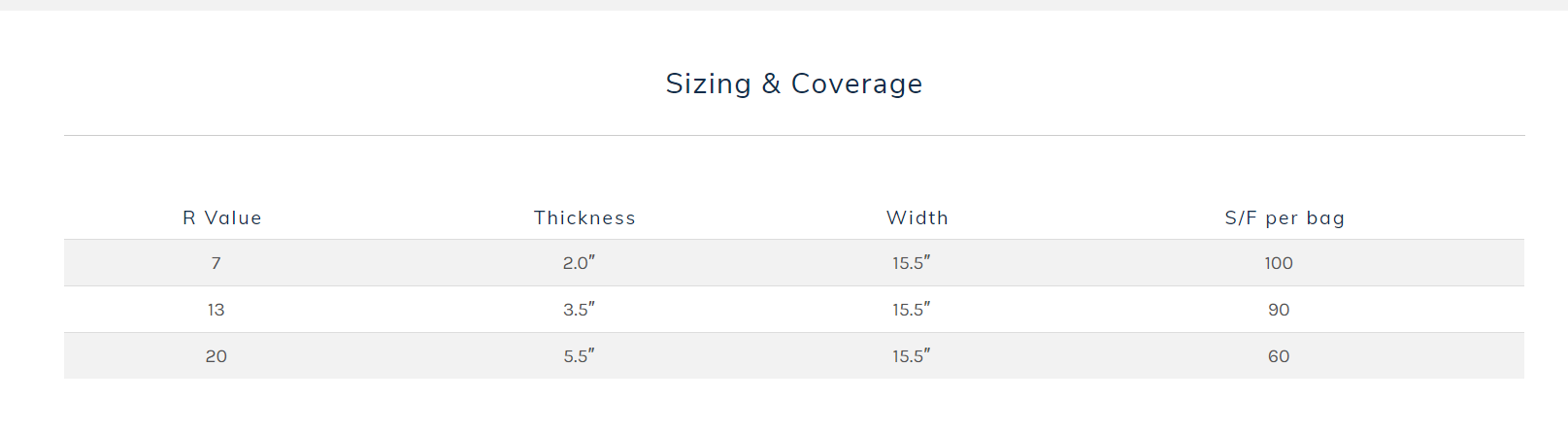

The most common way to measure insulation products is by R Value which denotes resistance to heat flow. The higher the R-value, the greater the insulating power. Havelock Wool comes in at an impressive R Value PER INCH of 3.6 for Batts and 4.3 for Loose Fill.

R Value is not the only way to measure insulation.

What happens when moisture is introduced into an environment? The R Value can plummet. In order to sustain high performance (high R Value), your insulation needs to actively manage moisture and stay dry. Havelock Wool does just that. Because wool is a hygroscopic insulator, it can absorb moisture without becoming wet to the touch and without affecting its superior performance.

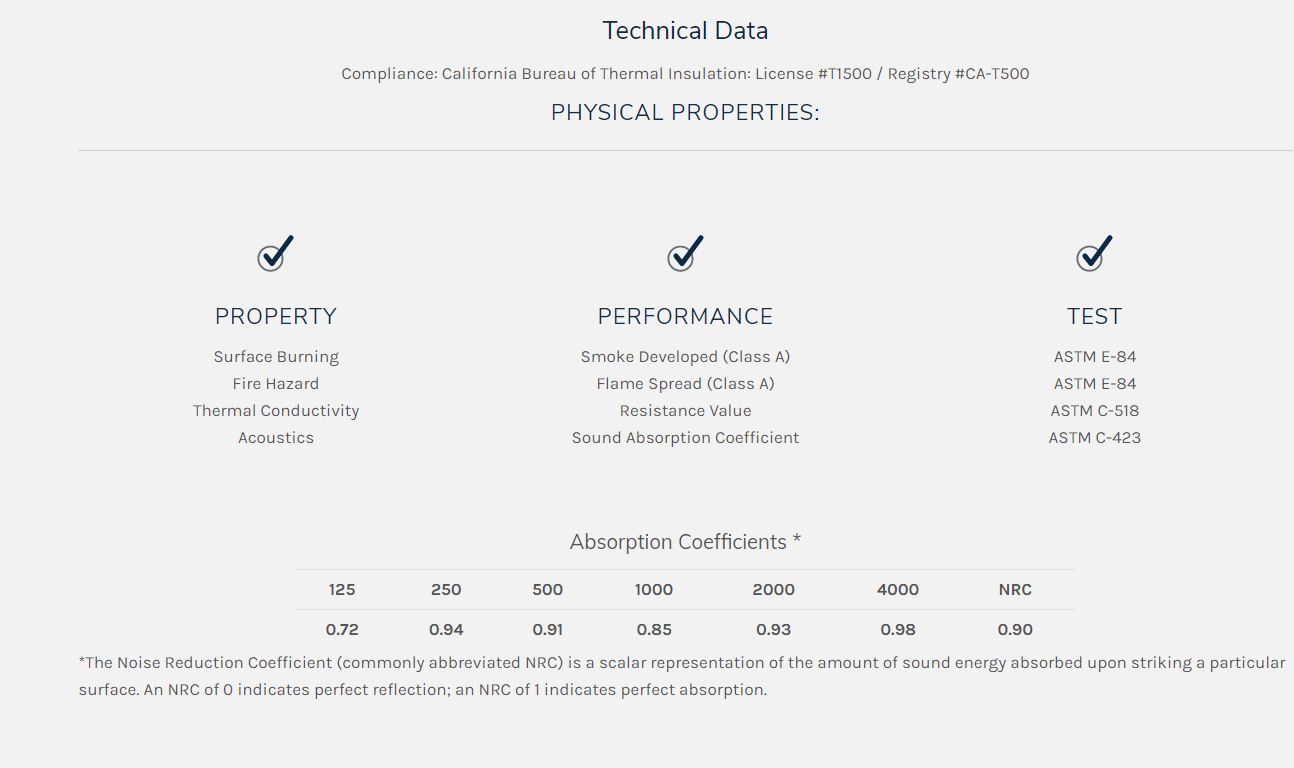

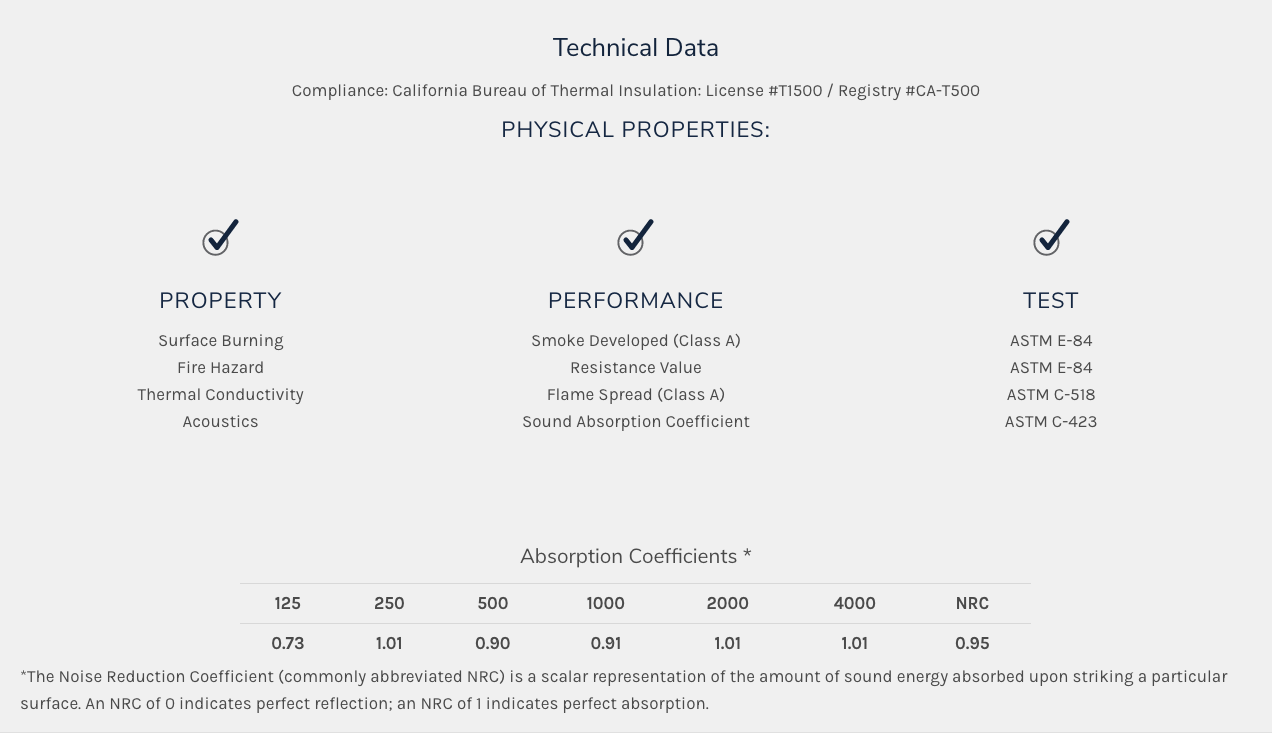

Havelock Wool is not only a great insulator but it excels at absorbing sound.

A Noise Reduction Coefficient (NRC) is a rating for how much sound a material absorbs. Like a sponge absorbs water, insulation absorbs sound and the NRC tells us just how much sound gets soaked up. The higher the NRC rating, the better the sound absorption. So a material with an NRC of 1 absorbs 100% of sound. In the insulation world, NRC is an important factor because along with regulating temperature, insulation should also keep your living space quiet.

Havelock Wool’s NRC of 90 and 95% (batts and loose-fill, respectively) beats most other insulation mediums. To be fair, there are some products with a slightly higher NRC but those tend to be designed specifically for sound absorption. As such, they fall short on other important metrics like R-Value…. not to mention moisture management, air filtration, and sustainability.

Havelock Wool is a truly sustainable building material, from its production to the end of its life. Our overall carbon emissions stack up extremely favorably compared to any other insulation material. It’s easy to understand as our raw material is not petrochemical-based and our process is not energy-intensive. We use repurposed textile machinery that runs on electricity. Further, wool is biodegradable and compostable unlike mainstream insulation which will sit in landfill, or, worse, on the ocean floor for the next 1,000 years. So after a very long life, wool can be placed back in the earth where it will break down on its own and actually fertilize the soil.

In the spirit of environmental transparency we have published an Environmental Product Declaration and a Life Cycle Assessment. These are third party data rich documents that provide in-depth details on our full environmental impact. Normally the employ of the professional building community but we believe everyone should use them to make informed building material decisions. See them HERE.

As the quality of building materials decline an increasing amount of chemicals and glues are used to reduce costs to attract consumer’s attention. These chemicals and glues are the major source of harmful substances like formaldehyde, So2 and NoX. As more homes are built to be airtight, the indoor air quality becomes compromised (see harvard study summary) and inhabitants face poor air quality challenges. Havelock Wool contains no harmful chemicals and the composition of the wool fiber acts as an air filter permanently abating these chemicals thru a complex structure of amino acids. Havelock Wool will block the movement of such pollutants as they try to migrate around the home. See here for an in depth research report from the University of Texas on wool’s ability to improve indoor air quality.

Yes, we conform to Class A of the building code for flame spread and smoke development pursuant to the ASTM E84 standards. There are no alternatives to this test.

How does Wool Resist Fire so Well?

Its interior composition explains why wool is fire resistant. Wool has a high nitrogen and water content so it needs higher levels of oxygen to burn than the surrounding environment provides. In addition, wool’s cell membrane structure will swell when heated to the point of combustion, forming an insulating layer that prevents flame spread.

Mold and Mildew are not part of a Healthy Home

A damp and moldy environment is detrimental to your health so it’s crucial that your home insulation resists mold and mildew to avoid an unhealthy living environment. Havelock Wool is a protein-based keratin thus naturally mold resistant.

Moreover, the outside of a wool fiber consists of overlapping cuticle cells that naturally repel water (hydrophobic). So water is not easily available on the surface for mold to grow.

Wool actively manages Relative Humidity

In a brilliant twist of evolution, the interior of the wool fiber is actually hygroscopic meaning it has a high moisture buffering capacity. Water vapor is able to pass into the interior of the fiber. This is how wool can absorb up to 33% of its own weight in water and still feel dry to the touch. So wool traps moisture inside the fiber (where mold spores cannot get to it) which moderates the relative humidity of your wall cavity and your living space.

Batt Insulation

Batt insulation takes a rectangular shape and it is designed to slide into the cavity of your interior walls. It is the cheapest and most common type available in the market. The efficacy of batt insulation is increasingly scrutinized by industry practitioners though the ease of install will allow for its dominant usage to persist.

Our product is all-natural, renewable and sustainable in it’s production, while being compostable at the end of an extended useful life. Wool is inherently self-extinguishing and manages moisture against 65% relative humidity. When it comes to energy efficiency, our batts perform similarly to other forms of insulation with an R-value of 4.3 per inch. Unlike others, no protective clothing is required for installation and one can argue the process is even a bit of fun.

Batts are typically cut at 48” and may need to be stretched slightly upon removal from packaging. Unfaced batts are applied with friction. A staple may be added at the installers discretion. Wire or lightning rods may be used in a ceiling joist or with metal framing. This video covers all aspects of batt installation: tools and materials needed, job site preparation and technique. https://youtu.be/gh2Woessyfg

Havelock Wool batts have no formaldehyde or chemical bonding agent of any sort.

Our batts are comprised of wool. Unlike other options, there is no synthetic mix in our products which means there is no glue or bonding agent. This greatly reduces the net embodied energy in our production process as no high heat is required. By comparison, mineral wool batts are bonded with extreme heat and the binder is formaldehyde.

Our batts are produced employing a mechanically driven needle punch. As a result, they are malleable, not rigid or difficult to manipulate. Some care should be taken in handling with an emphasis on the needled side, which should face out from the wall cavity.

Blown-In (Loose Fill) insulation

Blown-in, or loose fill, insulation is a more recent entrant into the insulation market. Installation begins with a membrane placed over open stud bays, or a hole poked in an existing wall, and insulation is blown behind.

Traditional batt insulation “slumps” overtime. This creates air gaps and a drop in insulation R-value. Blown-in insulation prevents this by filling your wall cavity more completely.

Our product is all-natural, renewable and sustainable in its production, while being compostable at the end of an extended useful life. Wool is inherently self-extinguishing and manages moisture against 65% relative humidity. Our blown-in out performs most other types of insulation with an R-value of 4.3 per inch.

Blown-in can be installed by hand for smaller projects though we recommend our rental blower for medium to large jobs. No prior insulation installation experience necessary!

This video covers all aspects of blown-in installation: tools and materials needed, job site preparation and technique.

Our blown-in insulation is comprised of 100% wool and no synthetic mix. We make small balls that are hugely effective at trapping air while avoiding slumping once installed. Some argue that entangling a straight fiber will actually allow it to expand over time. Irrespectively, the extra trapping of air allows for higher r values to be achieved.

No, blown-in is certainly quite easy to install in attics but has wide spread use in exterior walls of high performance homes. Commonly called a BIBS system by the pro’s (blown in blanket). Its higher value makes a compelling argument for use in the exterior envelope.

There are many kinds of insulation mesh, all will work fine as their only real purpose is to hold the wool in place until the drywall is installed to cover it all up. That said, the blower works better with netting as opposed to a mesh as it provides an escape path for the forced air. Apply staples every 2-3 inches and cut holes with a knife to make new ones for blowing.

No, not Havelock Wool. But, to be clear, traditional blown-in fibers are inherently weak, brittle and have a tendency to absorb moisture/water like a sponge. Under their own mass they will settle. In an attempt to prevent settling, these fibers are installed at high densities. Fortunately, the wool fiber has several built-in (natural) designs and chemistry to help prevent slumping. #1 It’s shaped like a spring. #2 When in the presence of vapor or water the individual fibers begin to move and also help fight slumping. It’s the reason you don’t see any moldy sheep.

No, in comparison to other blown in products like cellulose. Yes, there is a small amount of dust from wool and the blower. If a new build or a good size remodel, then there is little concern. If a small remodel is in the middle of your current living space, then you may want to section off the space you are blowing or consider hand stuffing the cavity. You can choose from 2 different mesh insulation retainers : non-woven mesh that has smaller holes to reduce dust, the other has bigger holes and allows for better visibility while blowing. Don’t forget to vacuum your stud bays and construction zone before installing Havelock as our blower will move existing dust around.

Yes, absolutely there is very little skill needed. We would point out that what is needed more than skill, is the desire to use better materials. Sadly, that is not the role of legacy insulation installers who have built their businesses around cheap, inferior and often toxic insulation products. Check out our blog for more on this topic.

Every municipality and climate zone has different recommendations for R values and code minimums. Havelock Wool Blown-in insulation is R4.3 per inch which allows for R24 in a 2×6 wall cavity. This typically exceeds code for exterior walls. Higher r-values can, of course, be achieved in larger cavities e.g. 2×10 or 2×12 ceiling joists.

Beside the insulation itself, air sealing is the single biggest performance gain you can achieve. Access is the toughest part. So, if you are removing all of your current attic insulation- now is the time to make your insulation go as far as possible. More information on air sealing can be found here.

Technically yes, in reality it does not work very well as the blower pushes wool through the hose with air pressure and this air pressure needs a way back out. Cutting more holes in a vapor variable membrane requires those holes to then be properly repaired. insulation mesh is cheap, it’s also faster to use it first ,then apply your smart membrane before the wall board.

Cans or recessed lights are rated by the manufacturer as IC or non-IC rated. IC stands for Insulation Contact. You will want to confirm by checking the individual light fixtures before starting your project. These too can be sieves for air leakage. A best practice would be to air seal the cans and move insulation around the cans – not over them.

Yes, our insulation passes the industry’s top testing threshold for home insulation. However, you want to adhere to codes and commonsense and have all connections sealed in junction boxes.

Yes, absolutely, it is our specialty to provide direct support for our blown-in products. Plus, we hear from our customers that it is quite simple once they understand the process. And some say it is borderline fun!

Your installer is probably a nice person but the unfortunate reality is insulation installers are not known for their willingness to use new and “healthy” products as they are often paid by the big insulation powerhouses to only sell and recommend their products.

Good questions but not to worry, we properly clean (scour) the wool before dipping it in a solution of boric acid (less than 1% by weight). This process should alleviate any concern for pests.

This is a tough one both for the DIY’er and the “professional” . While it is possible, we would caution against the need for a fair bit of trial and error. Also, we would recommend a video snake camera (Amazon for $40.00) to start looking into the walls for challenging areas like electrical, plumbing and fire breaks.

We provide blowers to DIYers free of charge with the purchase of 1 pallet of blown-in or more. Also, provided is instructional video and product support. Industry professionals should use their own machines.

No, not really. Those blowers are designed to aerate short, weak fibers. Havelock Wool fibers are polar opposite as the fibers are long and incredibly strong. Our wool fibers tend to wrap themselves up around moving hoppers, agitators and airlocks causing a lengthy headache to unwind. Yes, we’ve learned the hard way! Some of the best commercial wool blowers are actually insulation removal vacuums, most have these but are likely unaware of their intended use with our products.

We provide options for both but blown-in is quick and covers completely around pipes and electrical with minimal effort. And the higher r value is definitely not to be overlooked – it is 20% higher in a 2×6!

Other FAQs

Shipping is about as painless as it could be. Small orders ship via Fedex. Larger orders are shipped on pallets via national LTL carriers with tracking and lowered to your curb. To lower cost these carriers use 53′ semi trucks and trailers -just make sure you have access where your road and driveway meet.

Havelock customers seek out their own installer, handyman or go the DIY route. Finding someone to install our materials is just as delicate as finding the right person you trust in your home. Fortunately, there are an abundance of installers to churn though as good ones do exist. In reality our products install just like others on the market. Havelock Wool is a different insulation company with a wildly different fiber and this might be too wild for some who stick to the status quo.

We have provided this install video for you to see if installation is within your scope of competency. If not, please call all of your local installers and ask them for their daily labor rates as we do not have a contracted list of installers. You can measure and purchase the wool directly from us and have a handyman or installer do the work.

Animal welfare is one of many reasons we source our wool from New Zealand. Their Animal Welfare Act 1999 governs how animals are treated and is enforced quite strictly. See the document here.

The very last clause, 59, was added a few years ago by the Wool Industry and you will see that it is a ban on mulesing. While mulesing was never really conducted in NZ it is now illegal.

Wool fibres are not harmful in any way. It’s possible that mineral and glass wool fibres can absorbed by the body through the lungs has prompted a number of countries to distinguish certain insulation materials as potentially carcinogenic. Materials of this nature are typically 1-4 microns thick (one-four millionth of a metre), but wool fibers are 30+ microns which are much too large to be hazardous. No protective clothing or equipment is required to handle or install wool insulation.

Most existing houses have at least some level of insulation in the attic. Many houses over 15 years will find that the depth of existing insulation is usually quite small as old glass/mineral fibre will settle over time and will be much less effective. There are two choices here: the existing insulation can be removed or Havelock Wool can be placed over existing insulation. If you remove the existing insulation, be sure to take all the proper precautions including gloves and dust masks. If you decide to add Havelock Wool over the existing insulation you will improve the overall insulation of your home and you will also minimise the old insulation fibers from blowing around the attic space.

Embodied energy is the energy required to produce the material and manufacture it to a building-grade insulation standard. It is typically measured in kiloWatt Hours per cubic metre (kWh/m3). Wool insulation contains the least embodied energy of any insulation available, meaning that in a very short time, it will save more energy than will have gone into its production. Most common insulation materials will take many years to achieve this break-even point and some will never reach it at all. The embodied energy of Sheep Wool Insulation is 15kWh m-3 (54MJ m-3) which is less than half of that of cellulose insulation and one sixth of that of mineral wool.

Mice and other household vermin are neither attracted nor repelled by any form of insulation. They seek out a source of food and a source of heat nearby to each other. Once insulated, attic and cavity spaces become colder and less attractive to these animals, deterring them from nesting there. The best method to avoid unwanted vermin is to find and close up any gaps that will allow them to enter your building. Further, we do treat our wool with a slight amount of boric acid (less than 1%) which does deter mice.

The aim of insulating should be to follow the shape of your living space as closely as possible. If your attic is only used for storage, then you should insulate the floor because if you insulate the roof, you will heat your attic and your energy costs will be significantly higher. If you have an attic conversion, follow the shape of the plasterboard right around (craw space floor, walls, diagonal, small attic and back down) to ensure maximum performance.

Electric wiring in the attic is best left on top of the insulation. This will allow easy access for electricians in the future and can avoid heavily loaded wires from overheating.

With all the building jargon and terminology out there, it can be intimidating to even start a conversation about insulation.

With that in mind, we put together our list of key insulation terms. It is not exhaustive but with just a little background knowledge, the complexities of the built environment and insulation, in particular, will be much simpler. And this will help everyone make more informed decisions.

Insulation Terms

R-value is the resistance value of the insulation i.e. the limiting factor for thermal conductivity. The higher the number the more insulated the space.

Thermal bridging is when outside temperatures are conducted inside and vice versa. Think of a structural metal beam that runs from the outside, in. When that beam transports cold air (in winter) to the inside of the structure – that is thermal bridging.

Air-tightness is an increasingly measured element in building. An air-tight structure is considered more efficient. Often it is.

A convective loop is the cycle of air inside a room resulting in heat loss. Warm air rises, cold air flows downward.

Wind washing is when wind drive blows air through walls and insulation. Not only can this make your home cold (or hot) but it can also cause condensation.

Vapor drive diffuses moisture vapor into and through walls which causes condensation. It can move from outside to inside a house or inside to outside.

Types of Insulation

Batts are precut insulation designed to fit into specific cavities.

Blown-in or loose-fill is a blown application generally seen to reduce the potential for gaps in cavities.

Facing is a covering applied to one side of insulation. Popular with fiberglass.

A vapor barrier is any material (typically a poly film) used to resist the diffusion of moisture (or vapor drive… see above!)

Insulation Metrics

R-Value (again) measures insulation’s resistance to heat flow. As R-value increases, the better the insulation resists the transfer of heat.

Flame spread and smoke development measure resistance to flame and how much smoke is developed. Most insulation conforms to Class A of the building code by adding toxic flame retardants. Wool is naturally self-extinguishing.

Sound transmission coefficient (STC) is a rating scale used to measure the sound rating or deadening ability of a wall system.

Noise reduction coefficient (NRC) is similar to an STC except that it measures a material’s sound attenuation characteristics….versus a wall system which can have multiple components.

WUFI is the measure of an insulation’s ability to manage moisture.

Building Term

Joists are lengths of timber (or steel,etc) arranged in parallel to support floors or ceilings.

Studs are vertical framing pieces, usually wood and typically 2×4 or 2×6 measured at 16 or 24” on center.

Furring strips are wood or other material used to level a surface or bump out a cavity so that insulation can be installed.

Rim joists attach perpendicularly to the joists providing support for the ends of the joists while capping off the end of the floor.

On Center (O/C) is the measurement from the center of one stud to the center of another stud.

Eaves are the part of the roof that overhangs a wall.

Soffit vents are vents in a soffit (underside of an eave) that allows fresh air into an attic.

Baffles are chutes that channel from soffit vents into attic space. This helps reduce moisture in your attic.

Attic vents are placed on a roof to allow air flow.

A ridge vent is installed at the peak of a roof to allow air flow in an attic.

Download our Full Product Specification sheet which contains information on all our products including costs per square feet and testing data right HERE.